Discover essential resources like “35 School Principal Interview Questions and Answers” to prepare for your interview. Explore technical, behavioral, and situational questions to ace your interview confidently.

Overview of the Importance of Preparation

Preparing for a principal interview is crucial to standing out as a strong candidate. Researching the school and its community, practicing common questions, and understanding the district’s goals can significantly enhance your confidence. Familiarize yourself with potential queries about leadership, vision, and school culture. Reviewing your educational philosophy and past experiences ensures clarity in your responses. Understanding how to address technical and situational questions, such as budget management or conflict resolution, demonstrates your readiness. Tailoring your answers to align with the school’s values and challenges shows your commitment. A well-prepared candidate conveys leadership potential, problem-solving skills, and a clear vision for school improvement, making a lasting impression on the interview panel.

Key Topics Covered in Principal Interview Questions

Principal interview questions cover a wide range of topics designed to assess leadership, vision, and problem-solving skills. Common questions focus on educational philosophy, school culture, and strategies for improvement. Candidates are often asked about their experience in budget management, teacher inspiration, and conflict resolution. Behavioral questions explore how they handle challenges, such as parent-teacher relationships or academic underperformance. Situational queries test decision-making in hypothetical scenarios, while technical questions address financial management and resource allocation. Understanding these topics ensures candidates can articulate their vision, demonstrate leadership, and showcase their ability to drive school success, making preparation essential for a polished and confident performance during the interview.

Common Principal Interview Questions

Explore frequently asked principal interview questions, including strengths, weaknesses, educational philosophy, and strategies for fostering positive school culture and improving academic performance.

General Questions About Background and Experience

Be prepared to discuss your educational journey and professional experience. Interviewers often ask about your academic qualifications, teaching background, and previous leadership roles. For instance, they may inquire about your strengths and weaknesses, your educational philosophy, and how your experience aligns with the school’s mission. Additionally, questions like “Tell me about your professional experience as an educator” or “How does your background prepare you for this principal role?” are common. Highlight specific achievements, such as successful programs you’ve led or challenges you’ve overcome. Emphasize your commitment to education and your ability to inspire students and staff. This helps demonstrate your suitability for the principal position.

Leadership and Visionary Questions

Leadership and visionary questions assess your ability to inspire and guide a school community. Common inquiries include, “How do you envision fostering a positive and inclusive school culture?” or “What strategies would you use to inspire teachers and students?” These questions aim to evaluate your capacity to lead and motivate. Additionally, interviewers may ask about your approach to developing a vision for school improvement and how you would involve stakeholders in the process. Be prepared to articulate your philosophy on leadership, emphasizing collaboration, innovation, and a commitment to student success. Highlight specific examples of how you’ve driven positive change in previous roles to demonstrate your visionary leadership skills effectively.

Behavioral and Situational Questions

Behavioral and situational questions focus on how you handle real-life scenarios and challenges. Examples include, “Tell me about a time you resolved a conflict between teachers and parents” or “How would you address a decline in student engagement?” These questions assess your problem-solving skills, decision-making, and ability to navigate complex situations. Prepare by reflecting on past experiences and using the STAR method (Situation, Task, Action, Result) to structure your responses. Highlight your strengths, such as communication and empathy, while addressing areas for growth. Demonstrating a clear, thoughtful approach to challenges will showcase your readiness for the principal role and your ability to lead effectively in dynamic environments.

Leadership and Visionary Questions

Leadership and visionary questions assess your ability to inspire and guide. Topics include fostering a positive culture, strategies for inspiring teachers and students, and developing a vision for improvement.

How to Foster a Positive School Culture

Fostering a positive school culture requires intentional leadership, clear communication, and inclusive practices. Start by setting high expectations and modeling respectful behavior. Encourage open dialogue among students, teachers, and parents to build trust and collaboration; Celebrate diversity and promote equity to ensure all individuals feel valued. Implement programs that recognize student achievements and positive behavior, creating a supportive environment. Regularly assess and address any issues that may negatively impact the culture. By prioritizing relationships and shared goals, you can create a thriving, inclusive community that promotes academic success and personal growth for all stakeholders.

Strategies for Inspiring Teachers and Students

Inspiring teachers and students involves fostering a culture of motivation and growth. Provide professional development opportunities for teachers to enhance their skills and stay engaged. Recognize and reward their efforts to boost morale. For students, create a challenging yet supportive learning environment that encourages creativity and critical thinking. Encourage student voice and choice in their education to increase ownership and interest. Celebrate student achievements through various platforms to build confidence. Collaborate with teachers to design engaging lessons and integrate real-world applications. By fostering a sense of purpose and community, you can inspire both teachers and students to reach their full potential and strive for excellence.

Developing a Vision for School Improvement

Developing a vision for school improvement requires collaboration with teachers, students, and parents to create a shared understanding of goals. Start by assessing current performance and identifying areas for growth. Align the vision with the school’s mission and improvement plans. Communicate the vision clearly to all stakeholders, ensuring it is inclusive and achievable. Involve teachers in professional development to build capacity and foster innovation. Regularly monitor progress and adjust strategies as needed. Celebrate successes to maintain motivation and encourage continuous improvement. A well-defined vision guides decision-making and resource allocation, ensuring efforts are focused on enhancing student outcomes and school-wide success.

Behavioral and Situational Questions

Behavioral and situational questions assess problem-solving, decision-making, and leadership. Examples include discussing strengths, weaknesses, and approaches to conflict resolution, demonstrating how you handle challenges effectively.

Strengths, Weaknesses, and Educational Philosophy

When addressing strengths, highlight leadership skills, communication, and dedication to student success. For weaknesses, discuss areas of improvement, such as delegation or time management, and how you’re addressing them. Your educational philosophy should reflect a commitment to equity, innovation, and student-centered learning. Emphasize how your philosophy aligns with the school’s mission and fosters a supportive environment. Be specific about how you inspire teachers and students, and provide examples of strategies that promote academic excellence and personal growth. Demonstrating self-awareness and a growth mindset is crucial, as it shows your ability to adapt and lead effectively in a dynamic educational setting.

Approach to Conflict Resolution and Decision-Making

Your approach to conflict resolution should emphasize active listening, remaining neutral, and focusing on solutions rather than blame. Highlight your ability to bring parties together to find common ground and resolve issues constructively. For decision-making, explain how you gather input from stakeholders, weigh options, and align choices with the school’s mission and goals. Stress the importance of transparency and communication in building trust. Provide examples of how you’ve successfully managed conflicts and made tough decisions in previous roles, demonstrating your problem-solving skills and commitment to fairness. Show how your approach fosters collaboration and supports a positive school environment.

Handling Challenges in School Administration

Discuss challenges such as budget constraints, improving academic performance, and managing parent-teacher relationships. Emphasize proactive strategies like resource allocation, data-driven decisions, and fostering collaboration. Highlight your experience in addressing these issues, showcasing problem-solving skills and a student-centered approach. Mention how you align decisions with the school’s mission and involve stakeholders for support. Provide specific examples, demonstrating resilience and adaptability in overcoming obstacles. Show your commitment to continuous improvement and creating a positive educational environment, ensuring all challenges are met with innovative solutions and a focus on student success.

Technical and Situational Questions

Explore strategies for improving academic performance, managing budgets, and fostering parent-teacher relationships. Discuss approaches to situational challenges and technical aspects of school administration with practical examples;

Strategies for Improving Academic Performance

Improving academic performance requires a multifaceted approach. Principals can implement data-driven instruction, focusing on student progress monitoring and personalized learning plans. Professional development for teachers is crucial, ensuring they adopt effective teaching strategies. Encouraging a growth mindset among students fosters resilience and motivation. Additionally, fostering strong parent-teacher relationships and community involvement creates a supportive learning environment. Principals should also promote equitable access to resources and address individual student needs. By aligning these strategies with school goals, principals can drive measurable academic improvements and create a culture of excellence and inclusivity.

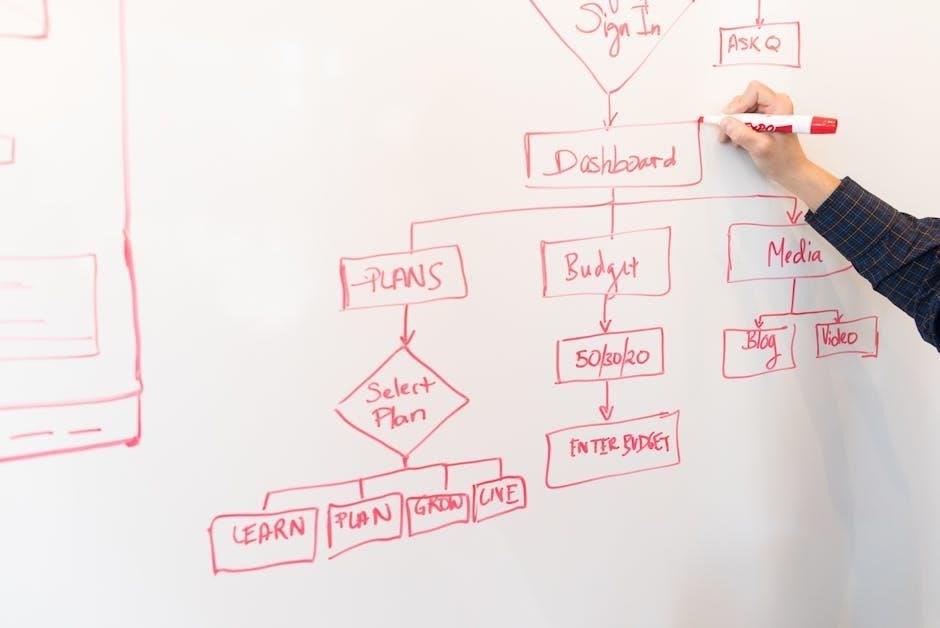

Managing School Budgets and Resources

Effective management of school budgets and resources is critical for ensuring operational efficiency and supporting educational goals. Principals must prioritize budget planning, aligning expenditures with school objectives and student needs. Transparent financial reporting and stakeholder collaboration are essential to build trust and accountability. Allocating resources equitably ensures all departments and programs receive adequate support. Principals should also explore ways to maximize funding through grants, partnerships, and cost-saving initiatives. Regular audits and financial reviews help maintain fiscal responsibility. By strategically managing resources, principals can create a sustainable environment that fosters academic success and extracurricular opportunities, ultimately benefiting the entire school community.

Approach to Parent-Teacher Relationships

Fostering positive parent-teacher relationships is vital for student success. Principals should encourage open communication, transparency, and collaboration between parents and staff. Regular parent-teacher conferences, newsletters, and digital platforms can keep parents informed about their child’s progress. Principals should also promote active involvement by inviting parents to participate in decision-making processes and school events. Building trust through consistent updates and addressing concerns promptly strengthens these relationships. Additionally, principals can facilitate workshops or resources to help parents support their child’s education. By fostering a sense of community and shared responsibility, principals can create a supportive environment where parents and teachers work together to enhance student outcomes and school success.

Preparation Tips for Principal Interviews

Research the school and its community, practice common questions, and present a clear vision and strategy for leadership. Be ready to discuss your educational philosophy and experiences.

Researching the School and Its Community

Researching the school and its community is crucial for a successful interview. Understand the school’s mission, values, and challenges to align your vision with their goals. Review the school’s improvement plan, academic performance, and extracurricular programs. Familiarize yourself with the student demographics and community expectations. This preparation demonstrates your genuine interest and readiness to contribute effectively. Knowing the school’s specific needs allows you to tailor your responses and showcase how your leadership can address them. Additionally, understanding the community’s expectations helps you highlight how you can foster partnerships and support student success. This thorough research ensures you are well-prepared to discuss your strategies and vision confidently during the interview.

Practicing Common Interview Questions

Practicing common interview questions is vital to ensure confidence and clarity during your principal interview. Review lists of frequently asked questions, such as those found in “35 School Principal Interview Questions and Answers” or “50 Interview Questions for Principals.” Focus on leadership, vision, and behavioral scenarios. Prepare thoughtful responses using the STAR method to structure your answers effectively. Practice articulating your educational philosophy, strengths, and strategies for school improvement. Use resources like PDF guides or mock interviews to refine your delivery. Understanding the school’s specific context will help tailor your responses. Regular practice ensures you can address challenges, inspire stakeholders, and present a clear vision with confidence and authenticity. This preparation is key to standing out as a strong candidate.

Presenting a Clear Vision and Strategy

Presenting a clear vision and strategy is crucial during a principal interview. Develop a compelling vision for school improvement by involving stakeholders like teachers, students, and parents. Align your strategy with the school’s goals and emphasize measurable outcomes. Highlight innovative approaches to academic excellence, such as integrating technology or fostering inclusive cultures. Showcase how your leadership will inspire teachers and students, driving collective success. Use specific examples from your experience to demonstrate your ability to execute plans effectively. Tailor your vision to the school’s unique needs, ensuring it reflects both short-term and long-term aspirations. A well-articulated vision and strategy will position you as a forward-thinking leader, ready to guide the school toward sustained growth and achievement.

Conclude your preparation by emphasizing confidence and authenticity. Follow up with gratitude and reiterate your vision, ensuring a lasting impression to secure the principal role.

Importance of Confidence and Authenticity

Confidence and authenticity are pivotal in a principal interview. Demonstrating self-assurance showcases your ability to lead effectively and inspire teachers and students. Authenticity builds trust, revealing your genuine commitment to education and leadership. Being true to your values and vision helps connect with the school community, fostering mutual respect and collaboration. Confidence also highlights your problem-solving skills and decision-making abilities, essential for managing a school. Authenticity ensures your responses align with your educational philosophy, making your leadership style relatable and trustworthy. Together, these qualities create a compelling impression, positioning you as the ideal candidate for the role.

By maintaining confidence and authenticity, you not only convey professionalism but also your passion for education. This approach leaves a lasting impact, reinforcing your suitability as a principal.

Following Up After the Interview

Following up after the interview is a crucial step in securing the principal position. Sending a thank-you note within 24 hours demonstrates professionalism and gratitude. Summarize key points discussed, reiterating your enthusiasm for the role and alignment with the school’s vision. This step reinforces your commitment and leaves a lasting impression. Personalize the message, addressing specific topics or concerns raised during the interview. A well-crafted follow-up not only shows respect but also highlights your proactive approach. It serves as a reminder of your qualifications and fit for the position, aiding the selection committee in their decision-making process.